Description

|

Product name |

Rock Wool Sandwich Panel |

Feature |

Environmental protection, Waterproof, Lightweight, Sound insulation, Heat insulation |

|

Refractory temperature |

1580~1770℃ |

Application |

Roof, Walls, Ceilings, Partition, Cold storage, Warehouse, Plant, etc |

|

Certification |

Steel Materials |

Conventional color |

White, Green, Blue, Gray, Red, etc., or according to customer's request |

|

Steel Materials |

Gi/PPGI/Aluminum/Stainless Sheet/Color Steel |

Length |

Customized |

|

Core Material |

EPS/PU/PIR/PUR/Rock wool/Glass wool |

Effective width |

Wall : 950mm / 1150mm, Roof : 950mm |

|

Sample |

Available |

Thickness |

Steel sheet thickness:0.4mm-0.8mm Panel thickness:50mm、75mm、100mm、150mm、200mm |

|

Specification |

Customized |

Density |

60-150kg/m3 |

|

Origin |

China |

Transport package |

PVC Foil Double Sides |

|

Production capacity |

300,000 tons/year

|

Trademark |

SHINHERO |

|

Material |

Polystyrene foam board(EPS/Glass wool/Phenolic Foam), Color steel sheet |

HS Code |

721070 |

|

Regular surface treatment |

PVDF,PE,HDP, SMP, etc. |

Delivery time |

15-25 days after we got T/T payment |

|

Usage |

Building |

Payment term |

30%TT Balance T/T and L/C both ok |

|

Name |

Rock Wool Sandwich Panel |

|

Outer layer |

Color steel sheet |

|

Steel plate thickness |

0.4mm-0.8mm |

|

Core |

Rock wool board |

|

Density |

60-150kg/m3 |

|

The thermal conductivity |

0.031-0.036W/M.K |

|

Length |

According to customer's request |

|

Thickness |

950mm、1150mm |

|

Thickness |

Steel sheet thickness:0.4mm-0.8mm Panel thickness:50mm、75mm、100mm、150mm、200mm |

|

Structure |

Upper and lower layer:color steel sheet Middle:ESP/Rock wool/Glass wool/PUR/PIR |

|

Color |

Any RAL color |

|

Feature |

Environmental protection, Waterproof, Lightweight, Sound insulation, Heat insulation |

|

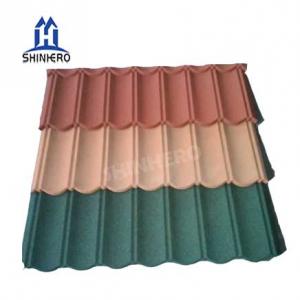

Application |

Roof, Walls, Ceilings, Partition, Cold Storage, Warehouse, Plant, etc |

We use our excellent equipment and technology and vast experience to manufacture products with stable quality under strict control throughout all process including pig iron manufacturing, steel manufacturing, heating, rolling and cooling.

2. Flawless Surface:

Using material (slabs) manufactured under a strict quality control system, we manufacture steel plates with flawless surface by removing scales from the steel plates with high pressure water jets during the rolling process. In addition, in the transport and heat treatment, etc. of steel plates, manufacturing is conducted using state-of-the-art equipment.

3. Wide availability:

We provide a wide product availability including steel plates that satisfy official standards in Japan and overseas, high tensile strength steel for welded structures, abrasion resistant steel, atmospheric corrosion resistant steel, low-temperature service steel, and steel for building, as well as materials that are suitable for a wide variety of uses,from offshore structures (production), line pipes (transport) tanks (storage) and other high-function steel for use in energy fields. In addition, we also accept orders for steel with special specifications, such as extra-thick steel plates for molds, electromagnetic soft iron, and chromium molybdenum steel for use in high temperatures. we also provide shot blasting and primer coating upon request. We also manufacture extra-heavy thick steel plates for use in nuclear power plants, thermal power plants, hydraulic power plants, petrochemical plants and the like.

4. On-time Delivery:

We strive for on-time delivery by making the most of the advantageous seaside location of each steel mill and our control systems for each individual product under process control that effectively utilizes a computer system.

5. Precise Consulting:

The engineering divisions at our head office and various branch offices canprecisely provide consulting on the quality characteristics, applications, and processing methods of steel plates as well as technical cooperation during use, based on their vast experience and comprehensive technical capabilities.

Sandwich panel is widely used in large industrial plants,warehouses,supermarkets,hospitals,stadiums,cold storage,portable room,multistory buildings,clean workshop and heat insulation fire place.

Below pictures are our projects: